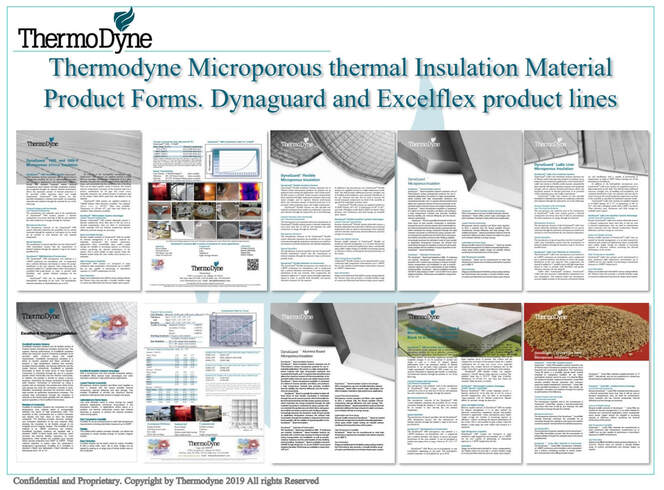

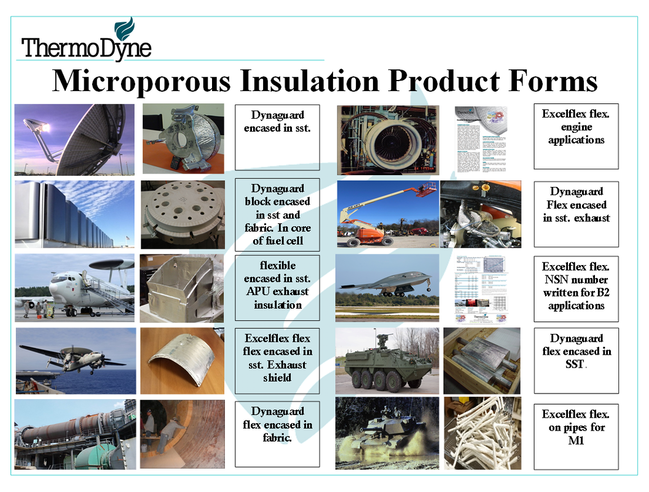

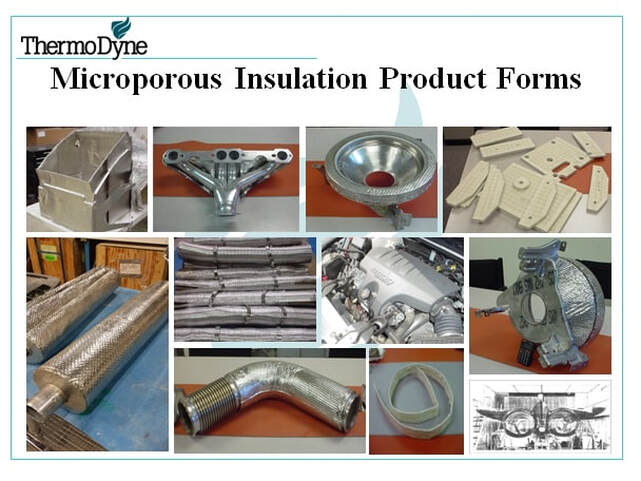

High Performance Thermal Insulation Materials and Highly Engineered Insulation Systems

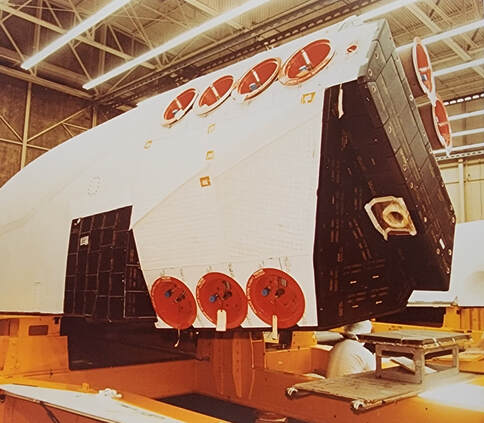

Large engineered thermal systems.Very small components. |

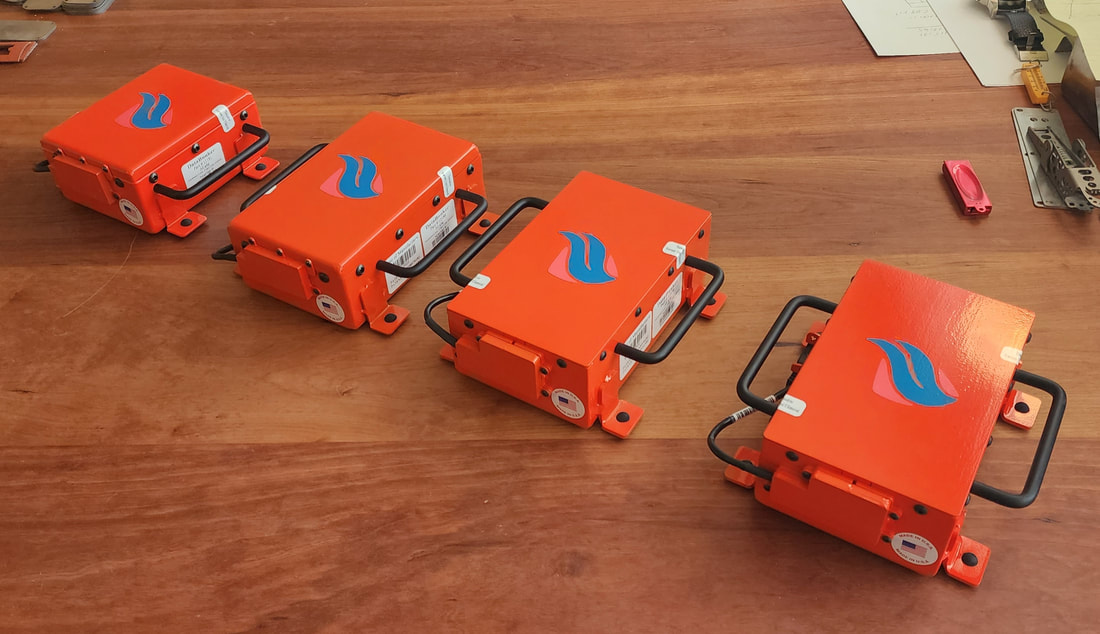

Crash Hardened memory storage.[email protected] Email for configurations available or for a response on a specific desired configuration. |

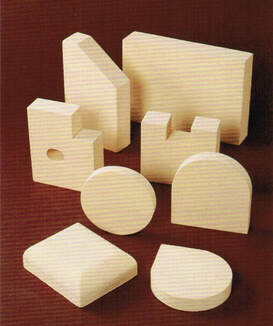

Detailed design and engineering for large systems.Detailed components. |

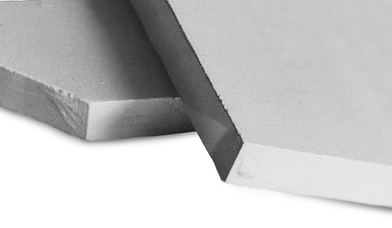

Very large monolithic super insulation blocks for large machined configurations. |

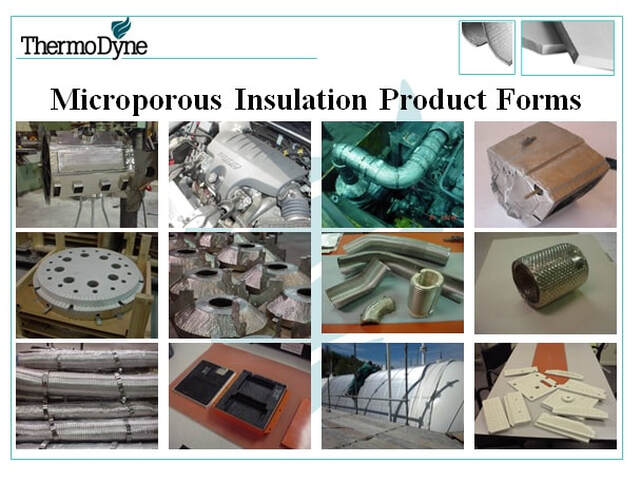

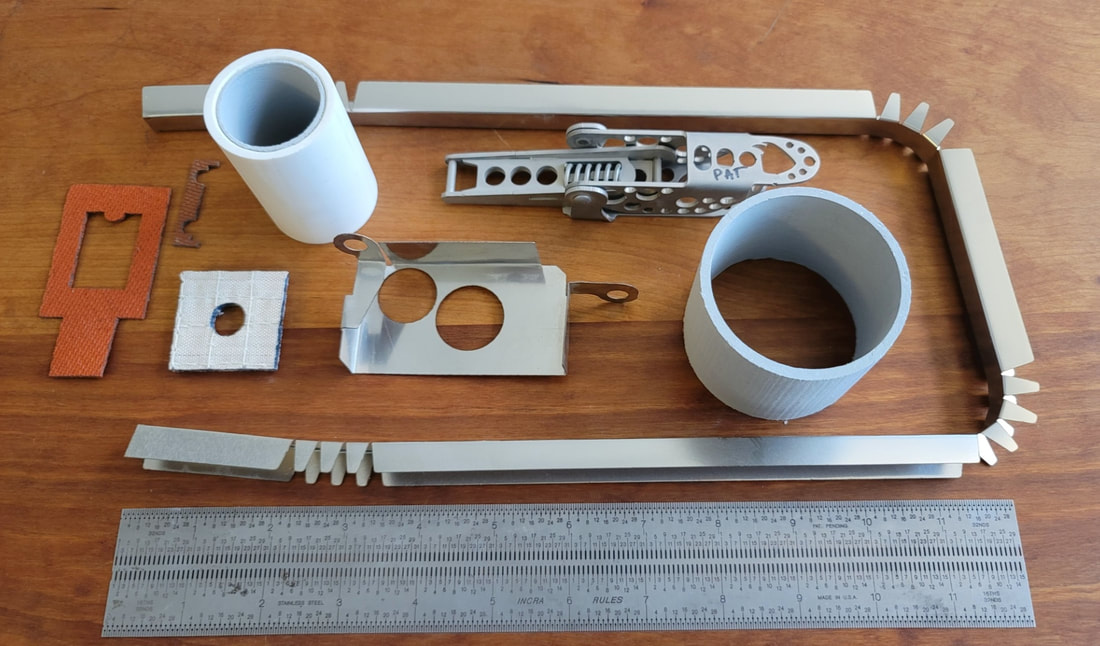

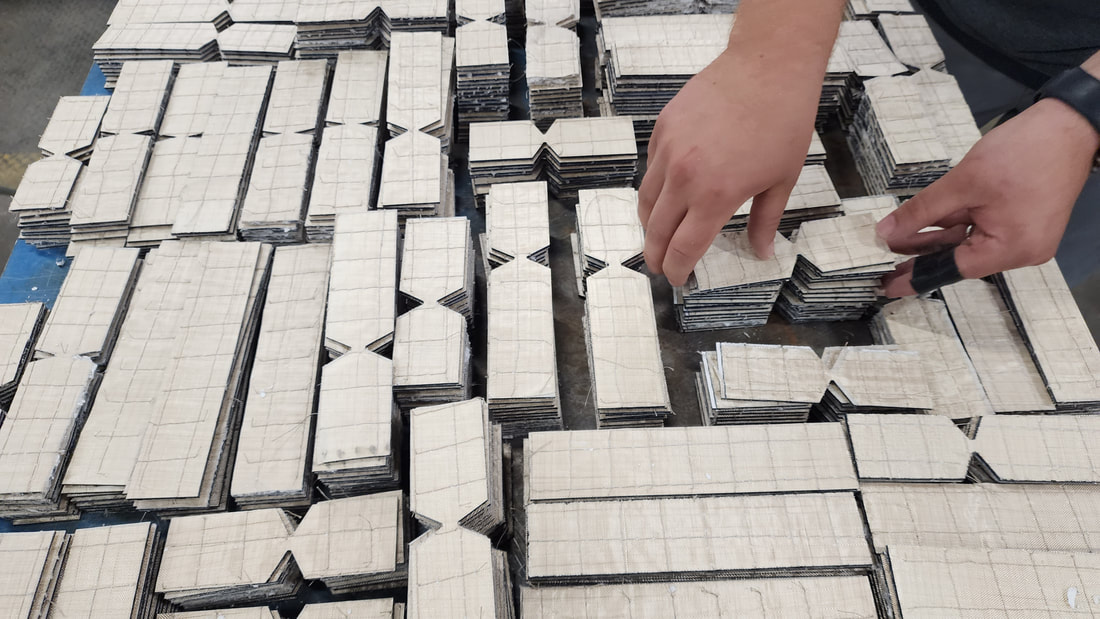

Extensive fabrication of our materials for customers applications. |

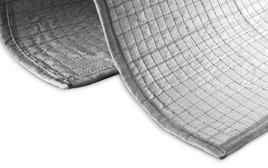

Flexible sheets for many applications. |

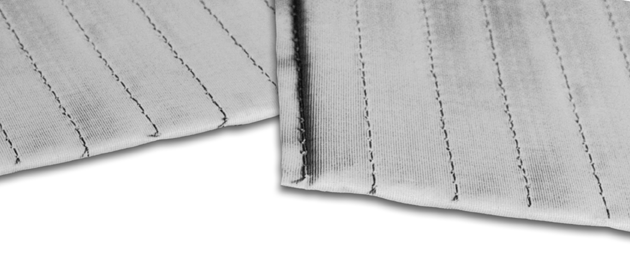

integration with customer supplied components.High degree of detailed integration |

High degree of detailed integration.Emissions-related shielding |